As society advances, the diversity of stamping products continues to expand, finding applications across various industries. To enhance efficiency, scrutinize work quality, and ensure product excellence, meticulous inspection of stamping parts becomes imperative. This article sheds light on prevalent inspection methods for stamping parts.

1. Flexible Gauze Mesh Grinding

Process:

Begin by cleansing the outer surface with clean gauze.

Employ flexible gauze mesh to systematically grind the entire surface of stamping parts along the longitudinal axis. This approach facilitates the identification of any pitting or indentations.

2. Touch Test

Procedure:

Clean the outer surface with gauze.

Don touch gloves and gently touch the stamping parts along the longitudinal axis, assessing the presence of discernible burrs, indentations, scratches, rough edges, etc.

Note: This method relies on the inspector's experience and is a swift yet effective examination technique.

3. Visual Inspection

Steps:

Inspect the surface for rust, cracks, sand holes, slag inclusions, burrs, or blemishes.

Quality parts exhibit precision and a lustrous finish. Crucial components demand higher precision and stringent anti-rust packaging.

Check for secure bonding between parts. In multi-part assemblies, tight adhesion, gluing, or welding is essential to prevent looseness.

Note: Visual inspection primarily identifies surface irregularities and macro defects in stamping parts.

4. Grinding with Oil Stone

Protocol:

Clean the surface using gauze.

Employ an oilstone (20 × 20 × 100mm or more), and smaller oilstones for areas with curves or challenging access.

Note: Opt for a fine-grained oilstone; the grinding direction should align with the longitudinal axis. Horizontal grinding may complement certain spots.

5. Inspection with Special Tools

Method:

Place metal stamping parts into inspection tools and follow the tool manual to perform the inspection.

6. Oiling Inspection

Procedure:

Clean the surface using gauze.

Evenly apply oil across the stamping surface in the same direction using a clean brush.

Inspect the oiled parts under strong light.

Note: This technique effectively reveals minor pits, dents, ripples, etc. on the stamping parts.

7. Adopt Approximate Process Testing

In actual production, process tests akin to stamping operations—such as tensile and bulging tests—are often utilized to assess material stamping performance, ensuring high product quality and qualification rates.

Characteristics of Stamping Parts

Rapid Process Completion: Stamping accomplishes feeding, stamping, delivery, and waste disposal in minutes, yielding tens or hundreds of parts per minute.

Uniformity and Precision: Unified molds generate uniform products with minimal errors and high dimensional accuracy. Random sampling of such products exhibits a weighing error below 3%.

Stamping Equipment

Mechanical presses are predominantly used for stamping, along with hydraulic presses for thick plates. Combining conveying machinery, die libraries, and rapid die-changing devices, automated stamping lines boost productivity, supported by computer program control.

Impact of Stamping Molds

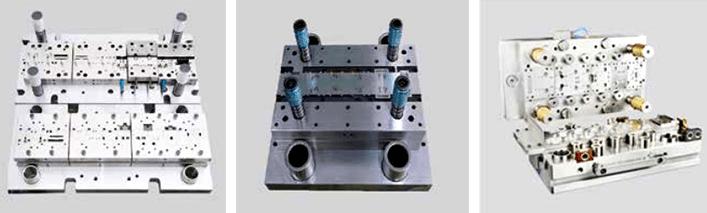

The precision and structure of stamping molds directly influence part formation and accuracy. Mold manufacturing cost and lifespan significantly impact part quality and cost. Mold design requires time, which extends preparation for new stamping parts.

Trends in Stamping Mold Development

Standardized mold bases and guide pieces.

Innovation in simple molds (for small batches), composite molds, and multi-station progressive molds (for large-scale production).

Advancements in rapid mold change devices, aiming to apply advanced stamping technology to diverse production scales.

The goal is to streamline production preparation, making advanced stamping technology feasible for both mass production and small-batch, multi-variety production scenarios.